Our cider takes at least a year from harvest to bottle. We take our time, because the results are remarkable.

Our apples come from walled gardens across the North East of Scotland. We have found that small apples from older orchards often release the most interesting flavours, when expertly handled by our seidear maker. Our apples are coming from our own orchard at Cluny Castle, from Haddo House walled garden, and from many small backyard orchards.

There would be no apples without bees, so we take good care of their habitat. On a sunny day butterflies are everywhere and the bees come out of their hive inside the old walled garden. The walled garden is a little oasis protected from the wind. It sometimes feels like visiting a different planet – time stands still here.

We check the apples for ripeness using old and new methods (iodine test, refractometer, biting into it). We think it is best to let the apples hang on until ripe. This takes time and requires several harvests off the same tree.

The apples are then shredded. Most cider makers press right after shredding. But we take the longer road, letting the apples macerate overnight. While this takes more time it gives us a beautiful ‘chapeau brun’ during the following, natural fermentation.

We ferment our cider without adding yeast during the first stage. This way the cider takes its own path, using yeast from the apple skin and the cidery. Natural fermentation must be closely monitored. The results vary and the process takes weeks to months to complete. Again, we take our time – because deep flavours cannot be rushed.

The good people of Normandy invented this natural process and called it “keeving”. We are the first to our knowledge who have successfully keeved in this latitude. Keeving locks in the fruitiness of the Scottish apples.

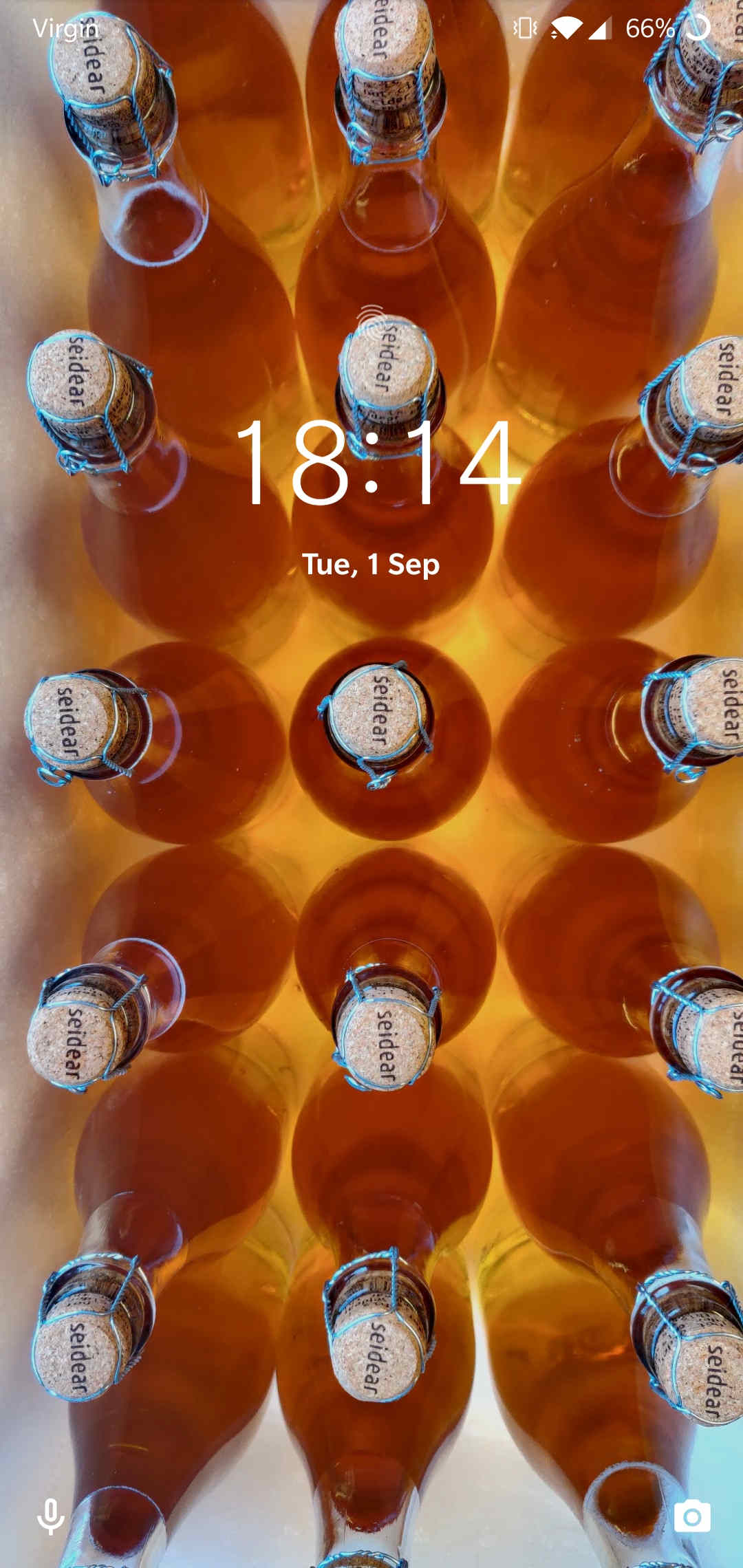

When fermentation slows considerably we fill our golden juice into extra-strong Champagne bottles, where the fermentation continues. The bottles are stored horizontally in a cold place; no problem with that – we are in Scotland!

After at least 6 months we place the bottles into a rack with the neck pointing slightly downwards. We turn them by hand every day for a few weeks. This process is called riddling. The purpose of riddling is to move all the yeast and sediments into the neck of the bottle, so we can remove it in the next step. Before popping the bottles, the neck of the bottle is frozen to lock the yeast in place.

Now comes our favourite part: popping hundreds of Champagne bottles as quickly as you can, one after the other!!! The great pressure inside the bottles shoots the ice plug out leaving behind a crystal clear, naturally sparking cider.

Finally, after about a year from harvest, the bottles receive their cork and wire cage and are ready for consumption – cheers!